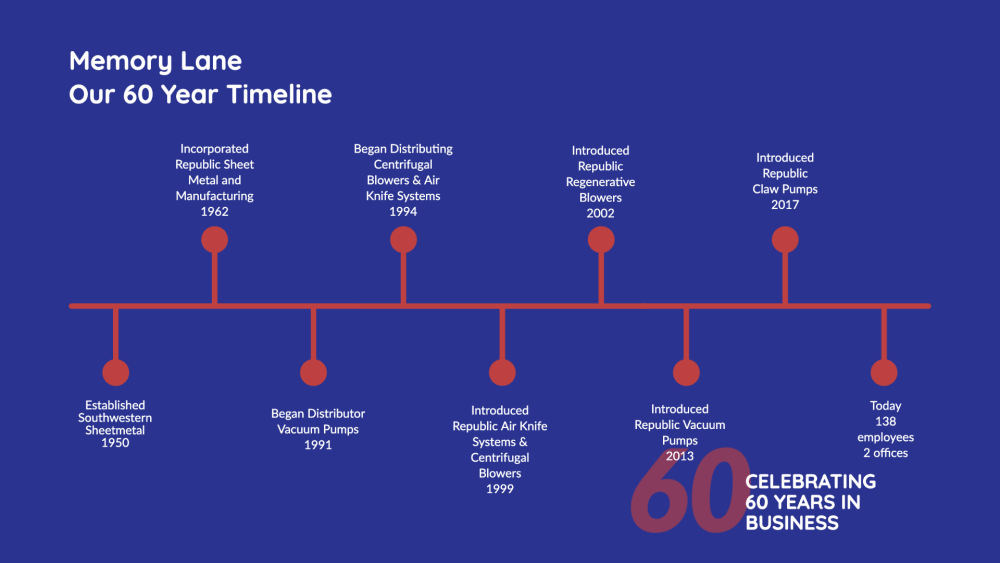

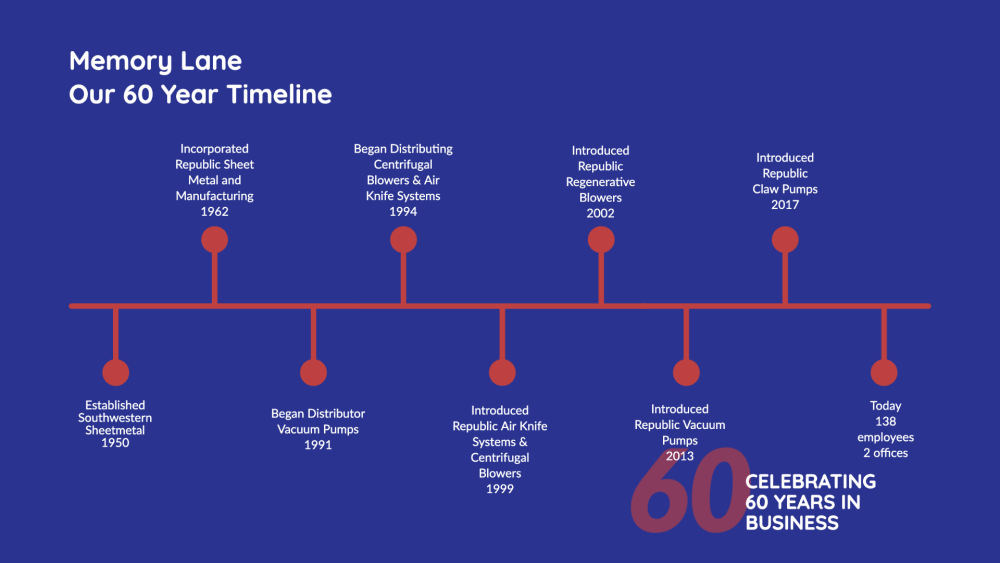

Republic Manufacturing Celebrated our 60th Anniversary in 2022.

Republic's Founding

Travel back to the summer of 1962 in Dallas, TX. President Kennedy was in office, and Ray Charles could be heard on radios everywhere singing “I Can’t Stop Loving You.” Women wore “lady-like” boxy skirt suits, and children ran freely through the neighborhood. James Goff and his sons Jimmy and George reinvigorated Southwestern Sheet Metal by incorporating a metal fabrication business called Republic Sheet Metal and Manufacturing Company.

Upon George’s death, the business passed to his son George. Wanting to keep the company legacy going, George brought his son Zach into the business in 1992. The company owned no computers, and all metal was cut by hand. George’s background was in distribution. He suggested that Republic start distributing industrial vacuum pumps – the company’s first line of equipment. As the distribution became more successful, Republic began distributing centrifugal blowers, air knives, positive displacement blowers, and regenerative blowers. As sales of the distributed items increased, Zach quickly realized that the company needed to begin repairing the pumps and blowers. Pretty soon, the distribution and repair business outpaced the fabricated metal.

Watch an interview with Owner and CEO Zach Goff.

Republic's Growth

Zach realized he consistently lost metal fabrication business to the competition due to price. After he learned that the competition was using CNC equipment, which allowed them to operate with lower costs, Republic invested in their first CNC equipment, thus ushering Republic into the modern era.

The introduction of the CNC equipment opened a novel opportunity – Republic could manufacture their own centrifugal blowers and air knives. Zach hired the company’s first engineer who designed Republic’s first centrifugal blower, and the company began manufacturing air movement equipment supported by the metal fabrication business. Zach continued investing in the company’s equipment and people, and Republic’s manufactured product line expanded.

The heart of the Republic has always been rooted in its products. Over the years, Republic has learned that getting the products right requires the right tools, people, and processes.

Technology plays a massive role in the advancement of the company. Now equipped with state-of-the-art machinery, Zach’s many investments include Trumpf lasers, Trumpf TruBends, Mazak Mill Turns, Mazak Horizontal Machining Center, Mazak Vertical Machining Center, and Mazak Turning Centers, a powder coating booth, and Zeiss quality machines. Software such as Trumpf Boost, AutoCAD, SolidWorks, Autodesk Inventor, and Ansys advances Republic’s capabilities beyond the mom & pop shop of the ’60s.

Increasing from 15 to over 115 employees creates its own set of challenges. To recruit the best talent possible, Zach invests in his employees through higher-learning courses, excellent 401K matching, attractive salaries, and complete benefits packages. Obtaining and retaining top talent is a key to Republic’s continued success.

Over the last 30 years of his employment at Republic, Zach has learned that there will always be significant problems in manufacturing. However, all of the issues eventually get solved. “We figure it out one way or another,” he says. With 60 years under its belt, Republic isn’t going anywhere. Manufacturing is alive and well at Republic Manufacturing in Dallas, TX.