Aluminum vs. Stainless Steel Air Knives – Choosing the Right Material for Your Application

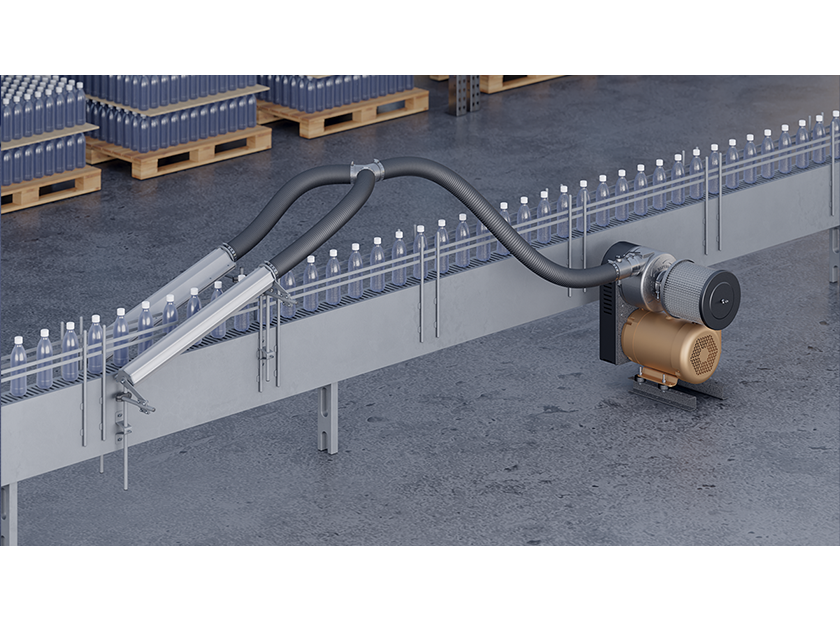

Air knives are essential in many industries, providing efficient drying, cooling, and debris removal for various production processes. They use a high-velocity air stream to blow off moisture, dust, and contaminants, ensuring clean and efficient operations.

When selecting an air knife, material choice is crucial. The two most common options are aluminum and stainless steel, each offering unique benefits. Understanding the differences between these materials will help businesses choose the best air knife for their specific industry and application.

Aluminum Air Knives

Key Characteristics

Aluminum air knives are known for their lightweight and durable construction. Their thermal conductivity helps dissipate heat efficiently, making them ideal for applications where temperature control is necessary. Additionally, aluminum air knives are a cost-effective solution without sacrificing performance.

Best Industry Applications

- General Manufacturing: Used for drying and cooling parts on conveyor belts and production lines.

- Electronics: Removes dust and debris from delicate components without static buildup.

- Food Processing: Ideal for drying food products before packaging, ensuring freshness and reducing contamination risks.

- Printing & Packaging: Ensures surfaces are clean and dry before labels, adhesives, or ink are applied.

Aluminum air knives are the go-to choice for light to medium-duty applications, offering reliable performance at an affordable price.

Stainless Steel Air Knives

Key Characteristics

Stainless steel air knives are engineered for demanding environments where durability, corrosion resistance, and high-pressure performance are critical. These air knives can withstand harsh chemicals, extreme temperatures, and sanitary environments, making them the preferred choice for industries requiring strict hygiene and long-term reliability.

Best Industry Applications

- Food & Beverage: Meets FDA and USDA compliance for hygienic processing and packaging.

- Pharmaceutical & Medical: Ideal for cleanroom environments where contamination control is essential.

- Automotive & Aerospace: Used in paint drying and surface preparation for precision manufacturing.

- Chemical Processing: Withstands aggressive chemicals and extreme environmental conditions.

Stainless steel air knives are ideal for heavy-duty applications where longevity and resistance to environmental factors are key considerations.

Comparing Aluminum vs. Stainless Steel Air Knives

| Feature | Aluminum Air Knife | Stainless Steel Air Knife |

| Material Strength | Lightweight, easy to handle | Heavy-duty, built for high-pressure use |

| Corrosion Resistance | Good, but not ideal for harsh environments | Excellent, resists rust and chemical exposure |

| Cost | More affordable | Higher initial investment, but longer lifespan |

| Best for | General manufacturing, electronics, food, printing | Food & beverage, medical, automotive, chemical processing |

Choosing the Right Air Knife for Your Industry

Selecting the right air knife involves considering several key factors:

- Environmental Conditions: If your process involves high humidity, chemicals, or extreme temperatures, stainless steel is the best choice.

- Budget Constraints: Aluminum air knives are more cost-effective, making them ideal for businesses looking for affordable efficiency.

- Durability & Longevity: Stainless steel air knives last longer and require less maintenance, reducing downtime in the long run.

- Industry Regulations: Industries like food processing and pharmaceuticals require sanitary, corrosion-resistant equipment, making stainless steel the preferred option.

By assessing these factors, businesses can ensure they choose an air knife that maximizes efficiency, reliability, and cost-effectiveness.

Choosing the right air knife material ensures optimal performance and efficiency in your production process. If you need guidance selecting the best air knife for your industry, Republic Manufacturing provides expert solutions to meet your needs. Contact us today!