How Regenerative Blowers Benefit the Pharmaceutical Industry

The pharmaceutical industry operates under strict regulations to ensure product safety, cleanliness, and efficiency. From drug manufacturing to packaging, maintaining controlled environments is essential.

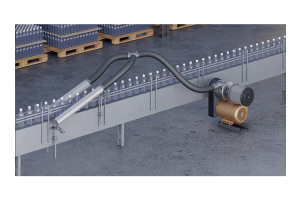

One critical component in pharmaceutical production is airflow management, which plays a vital role in conveying materials, drying, and maintaining contamination-free environments. Regenerative blowers provide an efficient, oil-free, and reliable air movement solution that meets the industry’s high standards.

What Are Regenerative Blowers?

Regenerative blowers use a multi-stage impeller system to generate airflow and vacuum pressure. Unlike traditional compressors or pumps, they create continuous, non-contact air movement, making them highly efficient and low maintenance.

Key Features of Regenerative Blowers

- Oil-Free Operation – No risk of contamination, ensuring a sterile environment.

- Low Maintenance – Fewer moving parts mean reduced wear and tear.

- Energy Efficient – Uses less energy compared to traditional compressed air systems.

- Reliable Performance – Designed for continuous operation with minimal downtime.

Their ability to provide consistent airflow and vacuum pressure makes regenerative blowers ideal for pharmaceutical applications that demand precision, cleanliness, and efficiency.

Key Benefits of Regenerative Blowers in the Pharmaceutical Industry

1. Contamination-Free Operation

Pharmaceutical manufacturing requires strict hygiene standards, and regenerative blowers help maintain a clean and controlled environment. Since they operate without oil, there is no risk of lubricant contamination, ensuring product safety.

- Meets FDA and GMP (Good Manufacturing Practices) standards.

- Supports cleanroom environments by reducing airborne particulates.

- Prevents cross-contamination in drug manufacturing and packaging.

2. Vacuum & Airflow for Precise Material Handling

Regenerative blowers provide precise vacuum suction and airflow, making them ideal for handling delicate pharmaceutical products.

- Tablet & Capsule Conveying – Ensures smooth movement of pills and powders without damage.

- Bottle Filling & Labeling – Helps secure bottles in place, preventing misalignment.

- Sterile Packaging – Used in vacuum-sealing and protective wrapping processes.

3. Enhanced Drying & Air Knife Applications

Moisture control is essential in pharmaceutical production, especially in tablet coating, sterilization, and packaging. Regenerative blowers work with air knives to deliver high-velocity air streams for fast and uniform drying.

- Removes excess moisture from medicine bottles and blister packs.

- Aids in sterilization by preventing bacterial growth on surfaces.

- Improves coating adhesion on tablets by eliminating unwanted moisture.

By replacing compressed air systems with regenerative blowers, pharmaceutical companies can achieve faster drying times and lower energy costs.

4. Energy-Efficient & Cost-Effective

Compared to traditional vacuum pumps and air compressors, regenerative blowers offer significant cost savings due to their energy-efficient design.

- Lower power consumption results in reduced operational costs.

- Minimal maintenance requirements lead to fewer disruptions in production.

- No need for costly oil changes or filter replacements.

5. Compliance with Industry Standards

Pharmaceutical facilities must adhere to strict air quality and safety regulations. Regenerative blowers meet these requirements by providing:

- Oil-free, contamination-free airflow.

- Compliance with FDA and GMP guidelines.

- Support for cleanroom applications requiring precise air control.

By using regenerative blowers, pharmaceutical companies can ensure their operations remain compliant, efficient, and safe.

Common Pharmaceutical Applications for Regenerative Blowers

Regenerative blowers support various critical processes in the pharmaceutical industry, including:

- Tablet & Capsule Conveying – Enables smooth transport of pharmaceutical products.

- Air Knife Drying & Sterilization – Removes moisture and enhances sterilization efficiency.

- Vacuum Packaging & Sealing – Keeps medicines fresh and free from contaminants.

- Pneumatic Material Handling – Ensures safe transport of powders and granules.

- Cleanroom Air Circulation – Maintains strict hygiene standards.

For pharmaceutical companies looking to improve efficiency and maintain compliance, regenerative blowers provide a proven solution. If you're exploring air movement solutions for your facility, consider the benefits of regenerative blowers in enhancing quality, performance, and sustainability. Contact us today and see what Republic has to offer!